Rolls-Royce Dart

The magic of a name

Rolls-Royce is still a byword in automobile engineering, and their aero engines have been equally famous since the first half of the Twentieth century. The Dart is the name of a smooth-flowing,

fast-running English river, and Rolls-Royce named their first and at the time their most unique engine after it - unique for two reasons, firstly because it was the first turbine in the world

to drive a civil aircraft, and secondly on account of its striking simplicity.

The operating cycle of the propeller turbine (turbo-prop) follows that of the well-known jet engine. A large volume of air is sucked in at the front of the engine, compressed and blown out

behind the compressor into combustion chambers where fuel is continuously sprayed in and burnt. This releases enormous heat energy, with the result that incandescent columns of gas roar out of

the chambers, past the turbine blades which drive the compressor, and escape through the tail pipe into the atmosphere as a high energy jet-stream.

This is the noise you hear when a jet flies over, the roar coming from its turbines. Its power is in the form of thrust, derived from the 1,000 mile-per-hour acceleration it has imparted to the

air between entering and leaving the engine, like the recoil of a gun as it fires a shell. In just the same way, the thrust of a propeller derives from the acceleration of the air it pumps

through it, only of course there's much less acceleration, less noise but correspondingly more air. The noise you hear from a Dart engine is the high pitched whine of the low pressure compressor

rotating assembly. The reason for the noise is that the tips of the rotating parts are virtually travelling at supersonic speed.

The efficiency of either of these 'propulsive pumps' is highest when the speed of the air leaving it is the same as that of the aircraft itself, or in other words, when the slipstream is not

moving relative to the atmosphere and there's no wasted energy. It can never quite happen, but that is the theory, and when you have grasped it you can see why a jet is inefficient at the

slow-to-medium flight speed suited to the propeller, and why jet automobiles will never be built.

On the other hand, there are practical limits to the velocity which a propeller can impart to its slipstream - the blade tips soon reach the speed of sound and then aerodynamics are apt to go

haywire - and so it in turn is unsuitable for very high-speed aircraft.

Propellers were the logical choice when it came to deciding how to power the Viscount

But since speed costs money, commercial jets engines are mostly confined to long-range airliners, and so propellers were the logical choice when it came to deciding how to power the Viscount,

which was designed for economic cruising speeds over medium ranges. It was known that a propeller's economy might be combined with the smooth-running and compact simplicity of a turbojet, if the

latter's turbine were made big enough not only to turn the compressor, but to harness the remaining jet energy for driving a propeller.

In 1945 Rolls-Royce flew the first turbo-prop engines in the world

In 1945 Rolls-Royce flew the first turbo-prop engines in the world, two modified Derwent turbo-jets named Trent powering a Gloster Meteor fighter, and encouraged by the results began the design

of the Dart engine.

The Dart and the Viscount

To use the words of Rolls-Royce; “Pride of place in any history of the Dart must, of course, be given to the Vickers-Armstrongs Viscount because, almost certainly, the engine would never have

been developed but for the requirements of this family of aircraft“.

The earliest record relating to the design and development of the Dart Turboprop is a technical drawing dated April 4 1945, before the hostilities of World War Two had ended, and the dust had

settled, which was a very positive attitude for Rolls-Royce to take at that time.

Although the initial proposal for this engine originated at Barnoldswick, near Burnley in Lancashire, Ernest W Hives a director of Rolls-Royce decided that the project should be mainly based at

Derby. Lord Hives became Managing Director in 1946 and Chairman in 1950 as Lord Hives of Duffield, and retired in January 1957 having seen the Viscount enter service and the Dart become the most

significant turboprop engine of its time and arguably of all time.

The Rolls-Royce Merlin piston engine powered Boulton-Paul P.108 Balliol

Initially it was proposed that the engine should develop 1,000 shaft horsepower through a tractor airscrew and be fitted to a new RAF training aircraft. Two aircraft types were proposed, the

Boulton Paul P.108 Balliol and the Avro Athena. Armstrong Siddeley was offering their Mamba engine, which, later on also became a competitor on the Vickers-Armstrongs Viscount. The design time of

both engines soon slipped behind the airframe timescales and were dropped in favour of existing piston engines such as the Rolls-Royce Merlin.

The team of designers and draughtsmen were based in the Elton Road office block in Derby under the leadership of Lionel Haworth who was an engineering graduate from the University of Cape Town,

South Africa. Prior to starting on the Dart, Lionel and his team had been involved with the WR1 jet engine in 1941 followed by the RCa3, which was a three shaft axial flow jet engine. This then

led to the Clyde engine, for which the team were responsible for the reduction gearbox and compressors during 1944. Lionel’s deputy was Ralph Shire senior who was an ex RAF apprentice from Halton

and had been transferred from the piston engine design office. The remainder of the Dart team came from the Merlin Marine and Crecy design offices plus several fresh graduates such as Roy Heathcote.

Initial detail drawings were issued to the production department on 1 November 1945 and the final build of the RB.53 prototype as it was originally designated, was completed on July 10 1946

resulting in an incredibly short manufacture and build time for such a revolutionary engine. The RB designation stood for Rolls-Royce Barnoldswick.

Testing the Dart

Dynamometer testing commenced on 13 July 1946 and test runs in a hangar using a slave propeller on 7 July 1947.

Development did not go smoothly, as when the RDa1, as it was now known, was initially weighed it was found to be overweight at over 1,100 lbs against a target weight of 850 lbs. The oppositions

Mamba weighed in at a mere 707 lbs, so Rolls-Royce had to rethink the whole design, if they were to remain competitive.

Power runs also highlighted that the engine was only developing about 600 shaft horsepower, way short of the target of 1,000 shaft horsepower. Problems with gas and air leakage were experienced and

on some tests the turbines were cooled using compressed air from an external source. Starting was also problematical at times and often resulted in a welding torch being inserted into an igniter

access port in order to ignite the fuel vapour. Clearly these problems demanded a lot of changes from the design team to get back on track both in terms of weight and power.

The engine consisted of two stages of centrifugal compressor and two stages of turbine coupled together to make up a single shaft arrangement driving a reduction gearbox.

Weight savings were made by re-designing the reduction gearbox with helical gear teeth in place of the spur gear arrangement and incorporating the oil tank within a cast air intake casing. Magnesium

was also utilised instead of aluminium for all the casing castings, diffusers and compressor impellers but after only 100 hours of test running at 350 shaft horsepower numerous stress cracks were

found which resulted in the majority of components reverting back to aluminium, although the reduction gearbox and auxiliary gearbox casings survived in magnesium. One of the benefits of the

integral oil tank was that the hot oil helped to keep the air intake from icing up under certain flight conditions.

A Rolls-Royce Dart RDa1 was installed in the nose of Avro Lancaster NG465

Later a spray grid was installed in front of the propeller to allow icing trials to be conducted

A RDa1 was installed in the nose of Avro Lancaster NG465 and first flew 10 October 1947 carrying out the first flight trials of this new engine. During later flights a spray grid

was installed in front of the propeller to allow icing trials to be conducted.

Whilst the power development programme was continuing to reach the 1,000 shaft horsepower target, Rolls-Royce received a new requirement from the Ministry of Supply to produce a new variant of

the Dart for the proposed Vickers-Armstrongs Viceroy (later re-named Viscount) with an increase in power to 1,400 shaft horsepower. The increase in power proposed actually helped Rolls-Royce as

the power to weight ratio improved.

A reduction in air and gas leaks coupled with a change in internal components to improve the airflow and thermal power efficiency improved things dramatically. Over 100 shaft horsepower was gained

in the re-design of the combustion chambers to stop all the joints leaking air at the front and gas at the rear. The compressor module was subjected to a major re-design of the throat areas, static

and rotating vane angles and profiles in order to deliver a higher mass flow of air to the combustions and turbines. The turbine itself came in for some major changes to improve the aerodynamics

and to make the nozzle box and inner cone more rigid which cut down on the number of gas leaks from the discharge nozzles.

The end result achieved in various stages of development and involving numerous tests and the charting of the improvements gained, resulted in an engine achieving 1,250 shaft horsepower and

designated as an RDa4 and 1,400 shaft horsepower designated as an RDa3 for the Viscount. There is no reference to the RDa2 designation, which presumably was allocated to the aborted Balliol project.

Exclusively powered by the Dart

During early 1948 two RDa1 engines were installed on Vickers Wellington LN715 for continuation of the flight trials. This was the first aircraft to fly exclusively powered by the Dart.

Two RDa1 engines were installed on Vickers Wellington LN715

In 1948 the Viscount prototype G-AHRF was fitted with Mark 503 RDa4 Darts which produced 1,250 shaft horsepower, 150 horsepower below the original requirement. Naturally the prototype could cope with

these low power ratings by virtue of its light operating weights. After the Mark 504 RDa3 engines were installed the true payload capability of the aircraft could be explored under more normal

operating conditions. During the first ten months a total of 750 hours flying was carried out, giving Rolls-Royce a lot of data to work with.

An Airspeed Ambassador was also fitted with Dart engines

An Airspeed Ambassador was also fitted with Dart engines, and was another aircraft type operated by BEA at this time. A water spray rig was fitted to the forward port fuselage to allow continuation

of the icing trials, which resulted in several engine modifications to prevent the hazardous build-up of ice.

During 1949 the RDa3 was installed in a Douglas DC3 to allow Rolls-Royce to carry out more intensive flight trials. This aircraft mainly operated from the Hucknall Flight Test Establishment.

Rolls-Royce Darts fitted BEA Dakota G-ALXN

Rolls-Royce Darts fitted BEA Dakota G-AMDB

Note the 'BEA Express Air Freight' titles

A further two DC3 were modified, G-ALXN and G-AMDB, and started operations with BEA throughout Europe in early 1951 as freighters, giving them their first experience of the operational issues that

they would later encounter with the Viscount. Over a period of two years these aircraft accumulated a total of 3,870 flying hours without an unplanned removal. All this helped to convince the Air

Registration Board (now CAA) that this engine had a future in the powering of modern aircraft. These aircraft operated up to a ceiling limit of 25,000 feet which often caused comment from air

traffic control who found it hard to believe that a DC3 could be flying so high. No doubt the flight crew played on this and had some fun in their well-insulated cockpit as they sucked away on

their oxygen masks.

Production Viscounts were originally fitted with either

the Mark 505 RDa3 or the Mark 506 RDa3 engines

Production Viscounts, which were much larger than the prototype, were originally fitted with either the Mark 505 RDa3 engines or the Mark 506 RDa3 engines producing up to 1,400 shaft horsepower,

which became the standard engine on the BEA V.700 series fleet.

The Mark 510 was adopted by BEA and others

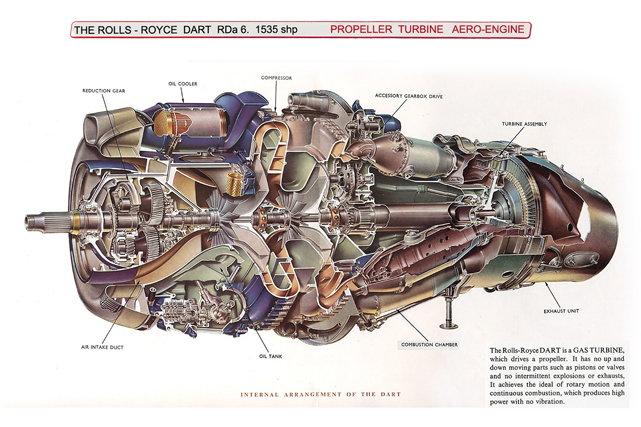

The next major change to the Dart resulted in the RDa6 family with a substantially re-designed engine producing 1,535 horsepower for the Viscount V.800 series. The Mark 510 was adopted by BEA and

others and some chose the Mark 515 variant. All this coincided with another increase in the size and weight of the Viscount. A lot of RDa3 Viscounts were upgraded to the RDa6 variant which changed

the profile of the engine cowlings from parallel to a more pronounced bulge, noticeable in many period photographs.

The RDa7 was installed in the Viscount as the Mark 520, Mark 525 and Mark 530

The engine was further refined to produce up to 1,835 shaft horsepower by totally re-designing the turbine module to incorporate three stages of turbine instead of two and an upgrade to the

reduction gearbox, compressor and combustion chambers. The maximum engine speed was also increased from 14,500 RPM to 15,000 RPM. This resulted in the RDa7 installed in the Viscount as the Mark 520

at 1,630 shaft horsepower, Mark 525 at 1,730 shaft horsepower and Mark 530 at 1,835 shaft horsepower. This family of engines allowed the Viscount to grow and evolve into a very useful commuter

aircraft with subsequent worldwide sales.

A larger variant was proposed at one stage to achieve over 2,000 shaft horsepower with a massively strengthened reduction gearbox designated as an RDa11 Mark 541 but this never materialised as the

Viscount model was never developed. The engine was however, developed and used in the NAMC YS-11, Convair 600 and 640 series (conversions from piston engines) and as a military engine for the Avro

Andover C Mark 1.

Rolls-Royce probably never expected the Dart to soldier on into the twenty first century, but they are probably not surprised that it has become one of the safest and most reliable engines of its

class. The downside to the Dart nowadays, is its high fuel consumption compared to more modern engines which consume less than half that of the Dart for the same power output. The sound of the

Dart will always remain memorable to most people who have stood and watched the numerous aircraft that this incredible engine was fitted to taxy in and out of national and regional airports around

the world.

Sadly, the Viscount is extinct operationally, but the Dart soldiered on at the begining of the twenty first century on the Fokker F27 Friendship, BAe 748, Gulfstream G159, NAMC YS-11 and a few

Convair 600 and 640 aircraft.

Other Rolls-Royce Dart powered aircraft

Handley Page HPR-7 Herald 201 - Photo source Steve Fitzgerald

Armstrong Whitworth AW-650 Argosy 222 - Photo source Ralf Manteufel

Fokker F-27-600 Friendship - Photo source Daniel Tanner

Hawker Siddeley HS-748 Srs2A/227 - Photo source Ger Buskermolen

Hawker Siddeley HS-780 Andover E3 - Photo source Fred Willemsen

Convair 640

Namc YS-11

Grumman G-159 Gulfstream 1

Breguet Br-1050 Alizé - Photo source Germain Chérot

The Breguet Br-1050 Alizé was a carrier borne aircraft that had a single Rolls-Royce Dart Mark 21 of

2,100 SHP and was used

by the French Aeronavale and the Indian Navy. This Dart had a mechanical

clutch that was employed on approach to a carrier to reduce the power transfer to the propeller while

the

engine revs were maintained at a high level. If the aircraft had to do a go-around, the clutch

would be engaged giving immediate power to the propeller. A total of 89 Breguet Br-1050

Alizé were built.